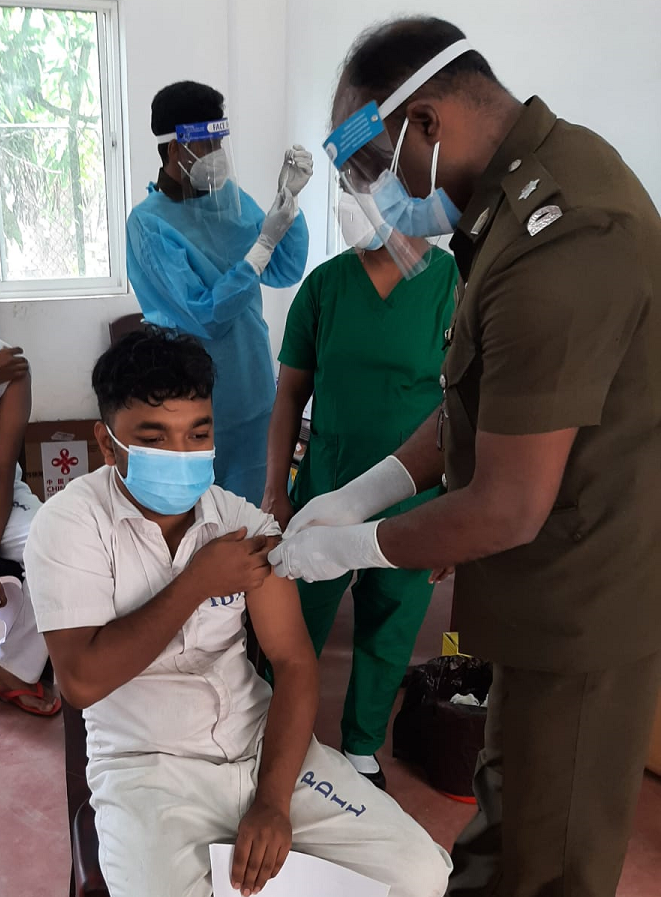

Supports the vaccination drive, offers free PPE and sanitization products, and conducts random Antigen tests weekly

Pelwatte Dairy, the local dairy giant, has taken prudent steps to accentuate its responsibility and resort towards guaranteeing wellbeing and security of its staff, customers, dairy farmers and different partners during the ongoing Covid-19 pandemic. All employees have been vaccinated at least with the first jab and health regulations are all adhered to all spaces. Weekly random rapid antigen tests and job security have helped the employees report to work with peace of mind.

Harshan Jeewakumara, Manager–HR of Pelwatte Dairy said, “We have been ensuring that all necessary health guidelines are met at all times. We have also taken steps to offer free packs that include sanitizers, masks, PPE and other essentials to our employees at the factory. We have also tried to ensure employees’ mental health as well”

The company’s resilience through the times has ensured that Pelwatte not only ensures its production processes but also be able to grow double the year before. Strict and contingent measures have been set up since the time the primary influx of the pandemic in Sri Lanka in March 2020. The organization ensured that all of its processes are kept in accordance to the Health Guidelines put forth by the authorities. Ensuring safety and security of the staff, customers, dairy farmers and all partners.

Harshan added saying “All of our employees have received at least their first jabs by now. Our partnerships with a leading hospital have allowed us to test at least 50% of the staff every week using antigen test kits. This ensures that all employees get tested twice a month. In case of any symptoms, they will be directed to the MOH for PCR tests; if tested positive and home quarantined – we have taken steps to provide them a essential food items pack worth Rs 5000 and also offer them necessary vitamins and herbal medicine during that period”

Pelwatte has been constantly supporting with the customary visits of the PHI and MOH to screen the organization and the entirety of its cycles. All factory premises, machinery and equipment are disinfected weekly by an authorized disinfectant company. Steaming equipment have been set up across the factory for sterilization purposes. Critical staff who are a high risk of getting infected are offered effective bio bubbles. Public places like cafeterias, washrooms and toilets are disinfectant or sanitized at least twice a day. The company has decided to only allow its staff to enter factory entrance.

The loading trucks and vehicles are routinely disinfected while the containers and pots used for assortment are cleaned, refined and sanitized very often. The drivers need to also go through a compulsory wash prior to entering the premises.

Pelwatte has thus far ensured job security to its staff, to its 10,000 + Dairy Farmers and many other families who provide auxiliary and supportive services in relative to the industry. The Company has been strengthening the industry and community. With the state decisions where the government expects the private dairy farms to meet the local demands; Pelwatte believes it will soon be a major stakeholder in the cause.